Name: EUC WOODWORK

Mobile: Whatsapp 86 136 2630 7530

E-mail: [email protected]

Add: NO.643 Qilu Avenue Weihai City Shandong Province China.

Skype: WATERSURFACE0631

QQ:

917669496

|

Product name : 03 heads sanding machine

Item : 130R-R-RP

|

| Details: | ||||||||||||||||||||||||||||||||||||||||||||

|

|

1st sanding roller diameter |

240mm |

|

2nd sanding roller diameter |

240mm |

|

3rd sanding roller diameter |

210mm |

|

Sanding work process width |

40-1300mm |

|

Sanding work process thickness |

2.5-150mm |

|

Feeding sanding item speed |

0-19m/min |

|

1st belt speed |

24m/s |

|

2nd belt speed |

24m/s |

|

3rd belt speed |

18m/s |

|

Sanding belt size |

1330*2200mm |

|

Total power |

63.62kw (86.5hp) |

|

1st belt motor |

22kw (30hp) |

|

2nd belt motor |

22kw (30hp) |

|

3rd belt motor |

15kw (20hp) |

|

Motors position |

INSIDE |

|

Feeding motor |

4kw (inveter) |

|

Lift & decline motor |

0.37kw |

|

Brush motor |

0.25kw |

|

Working pressure |

0.4-0.8Mpa |

|

Compressed air consumption |

1 m3/min |

|

Overall dimension |

2700*2000*2120mm |

|

Weight |

4900kgs |

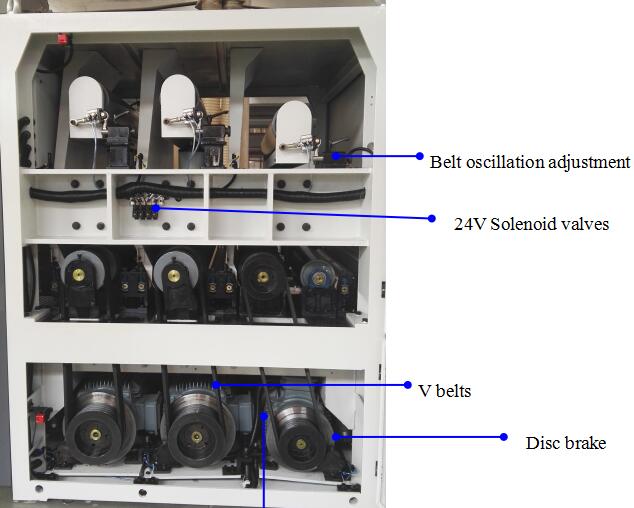

Sanding Units

1st sanding unit with diameter 240mm steel sanding roller complete with: sanding belt tension unit; electronic oscillation; dust hood; safety systems.

Sanding roller with helicoidal grooves for cooling.

Motor with one speed of rotation.

2nd sanding unit structure be same as 1st ,except rubber hardness be difference(shore70);

3rd sanding unit is a combination of rubber roller and pad,

with alloy rack, felt, graphite cloth complete with sanding belt tension unit; electronic oscillation; dust hood; safety systems.

Rubber roller is diameter 210mm and hardness 55 shore.

Sanding pad can be adjusted up and down easily. (Air pad is available)

Motor with one speed of rotation.

Machine manufacture meet CE regulations of European general machine directive.

Pressure units

Pressure units to hold the work pieces on the conveyor belt; are positioned in front and rear of each working unit;

The press rollers with springs to compensate panel thickness difference.

Feed system

Feed table is steel with tolerance of planarity within 0.05mm; table surface fine grind to avoid wear of the internal side of the feed belt..

Conveyor belt with surface in rubber at appropriate hardness; top profile according to operation requirement.

Drive unit with motor and converter, feed speed variable in continuous from 0m/min to 19m/min.

Feed table extension in machine front side with steel idle rollers.

Electric compoents in the front of machine, includes a main switch, PLC, contactor, breaker ,all be built on standard CE rules.

there are 02 sanding heads as optional also....

| Related Products : |

|

|

|

|

||||||||

|

Planer&Moulder Line

Planer&Moulder Line Four Side Moulder

Four Side Moulder